The Life of a Stone Quarry ...

Here at the Saracino Industries family of stone companies, we like to say, "one man's rocks are another man's treasure." This has been the case for centuries, where dusty, noisy, industrial stone quarry sites yield the finished, polished, pristine architectural stone exhibited on the world's most beautiful structures.

Granites, marbles, limestones, and other stones ordinarily occur in large bodies and are continuous for indefinite distances into the earth. Westchester County (located immediately north of New York City), by way of natural occurrence, is one of North America's most influential historical stone tracks, having provided native quarried building and monumental stone to some of most distinguished buildings and structures in the United States. Since as early as 1751, stone quarries have thrived in New York State for the purposes of lime manufacture and the making of iron, building and monumental stone, and road construction. In the centuries to come, granite quarries would eventually thrive in the cities just north of Manhattan. |

Quarry History of Yonkers, New York

|

Since as early as 1751, stone quarries have thrived in New York State for the purposes of lime manufacture and the making of iron, building and monumental stone, and road construction. In the centuries to come, granite quarries would eventually thrive in the cities just north of Manhattan.

The City of Yonkers, NY, will go down in history as one of the most prominent granite quarry locations in the United States. Yonkers Granite dominated the masonry and construction industry not only in New York City, but in areas that stretched as far north as Canada and as far west as Chicago. The noticeably familiar color and texture of Yonkers Granite set the tone for architects and project managers for centuries, a practice that continues through present day. The growth of the granite quarry industry in the region was particularly rapid in the decade from 1890 to 1900. |

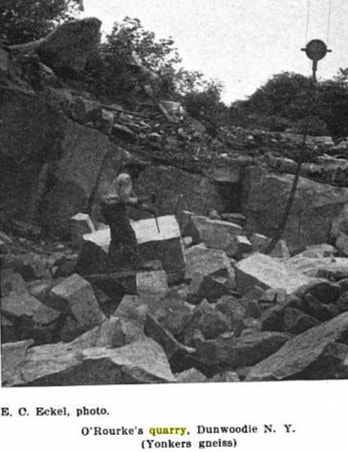

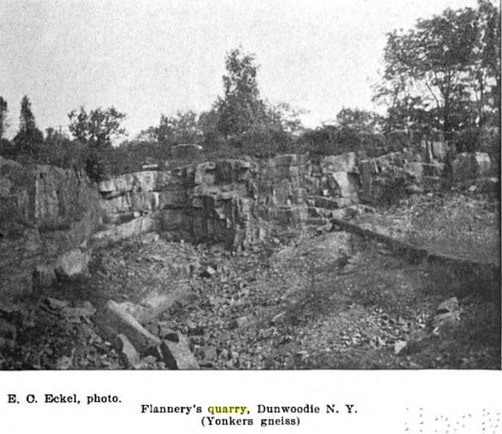

This was a period of remarkable advancement in all kinds of engineering work and manufacturing. A light-colored granite with a markedly foliate texture was discovered in the southern section of Westchester County, where it was the basis of rather extensive quarry operations in the early 1900s. Under the formal name of the "Yonkers Gneiss," it was clearly established as a prominent building stone.

In terms of geology, “Yonkers Gneiss” is the official term to describe the band of bedrock that occurs in a long, narrow belt, and also in isolated bodies in southern Westchester. It has also been known as Yonkers Granite, or Westchester Granite.

As in all the Yonkers Gneiss quarries, black powder was used when necessary, but much of the stone was extracted by use of the plug and feather method, which was used for splitting the stone to-size after it has been broken out in blocks.

The Yonkers Gneiss outcrops lie in several areas. The principal belt within which most of the quarries were situated parallels the former Bronx River and Harlem Railroads, from a point south of Mount Vernon up to Hartsdale. A second area of the Yonkers Gneiss extends along the axis of the main belt father north, near Valhalla and the Kensico Reservoir.

In terms of geology, “Yonkers Gneiss” is the official term to describe the band of bedrock that occurs in a long, narrow belt, and also in isolated bodies in southern Westchester. It has also been known as Yonkers Granite, or Westchester Granite.

As in all the Yonkers Gneiss quarries, black powder was used when necessary, but much of the stone was extracted by use of the plug and feather method, which was used for splitting the stone to-size after it has been broken out in blocks.

The Yonkers Gneiss outcrops lie in several areas. The principal belt within which most of the quarries were situated parallels the former Bronx River and Harlem Railroads, from a point south of Mount Vernon up to Hartsdale. A second area of the Yonkers Gneiss extends along the axis of the main belt father north, near Valhalla and the Kensico Reservoir.

|

Some of the earliest quarries, run by the Valentine Family of Yonkers, were operative around 1842, situated 2 miles southeast of Yonkers, on Mount Vernon road, but were abandoned shortly thereafter. The McCabe Quarry in the town of Scarsdale, about a mile east of Hartsdale, was opened in gneiss similar to Yonkers, but lying off the main belt. This quarry was mainly used for crushed stone, with some rough foundation stone.

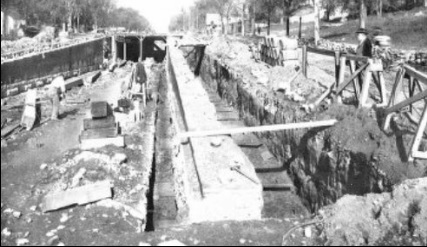

A small quarry once existed in the town of North Castle, about a mile northeast of Silver Lake, and was known as the Collins Quarry. Production was restricted to local needs and closed in the early 1900s. Yes, the quarry work in the Yonkers belt had carried on for a long time, but until about 1890s did not reach any considerable proportions. After the Valentine quarry, most of the quarries in Yonkers were opened around 1892. At that time, there was unusual activity in building and engineering construction, particularly by the railroads, which had a great deal of work in connection with bridges and retaining walls under way. The market for stone was mainly local. A simple hack-and-hew business in the 1890s with few customers, the quarries got their first big order with the building of the New Haven Railroad cut in Mount Vernon in 1902. Granite from the quarries was used for retaining walls there, and provided its durability and utilitarian beauty. |

Operated by the Hackett and O’Rourke families in the early days, the quarries of Yonkers were brought in a cooperation of architects who knew good stone when they saw it. A man named Joseph Saso brought about the first big expansion of the quarries, taking it into the school and church field on a large scale.

The prosperity of the Yonkers quarries can be mainly attributed to the Hackett brothers of Yonkers, who had operated a quarry for many years in the northern part of the main Yonkers belt. Their property lied about one mile north of Dunwoodie, at the junction of Midland Avenue and Central Avenue, and was open for a distance of 800 feet along the course of the gneiss. The Hackett brother’s quarry mainly furnished building stone, which was its chief product.

Stone from the Hackett quarry can still be seen on structures such as St. Joseph’s Seminary, Dunwoodie; St. Joseph’s Hospital, Yonkers; St. John’s Hospital, Yonkers; and Public School buildings nos. 3, 9, 10, 15, 180, Yonkers. Examples of the Hackett’s Yonkers Stone, with a shiny polished finish, are also seen in the columns of the County Jail at White Plains.

The prosperity of the Yonkers quarries can be mainly attributed to the Hackett brothers of Yonkers, who had operated a quarry for many years in the northern part of the main Yonkers belt. Their property lied about one mile north of Dunwoodie, at the junction of Midland Avenue and Central Avenue, and was open for a distance of 800 feet along the course of the gneiss. The Hackett brother’s quarry mainly furnished building stone, which was its chief product.

Stone from the Hackett quarry can still be seen on structures such as St. Joseph’s Seminary, Dunwoodie; St. Joseph’s Hospital, Yonkers; St. John’s Hospital, Yonkers; and Public School buildings nos. 3, 9, 10, 15, 180, Yonkers. Examples of the Hackett’s Yonkers Stone, with a shiny polished finish, are also seen in the columns of the County Jail at White Plains.

The rock is characteristic Yonkers Stone; being rather fine in grain, and of slightly blueish-grey color. This color becomes more of a pink on the cleavage surface within the quarry. Hammer-dressed surfaces exhibit medium-grey.

In quarrying during the late 1800s and early 1900s, the stone was broken-out using black powder. Holes were put down about 10 feet deep by a steam drill. This method yields a large quantity of material unsuited for building stone, and thus finds its way to road construction and other foundation work. Shipments were typically made by rail, via the Putnam Division of the New York Central Railroad.

In quarrying during the late 1800s and early 1900s, the stone was broken-out using black powder. Holes were put down about 10 feet deep by a steam drill. This method yields a large quantity of material unsuited for building stone, and thus finds its way to road construction and other foundation work. Shipments were typically made by rail, via the Putnam Division of the New York Central Railroad.

|

In the early 1900s, architectural stone using Westchester Granite became prominent in the Yonkers quarry area, thanks to Louis Perri. The Perri Quarry, which was situated on the east side of Central Avenue (across from the Hackett property), was mainly used for smaller work, such as custom sills and lintels. All work was done by hand. The Perri Family created a lasting art of hand-crafted stonework in the Westchester area.

In addition, one of the earliest stone fabrication plants in Westchester County was the Mount Vernon Plant of A.T. PETRILLO CO., founded in 1907. This organization provided the cut stone for many structures throughout New York City, including the United Nations Building on E 42nd Street. |

By the year 1913, the production of stone in New York State was valued at over $6.7 Million for building stone purposes. As an architectural stone, granite outranked other igneous rocks in the state (such as marble). Its prominence was due in part to its relatively widespread occurrence, but largely to the combination of qualities in regard to color, uniformity in texture, and ease of extraction.

Another small quarry had opened in Yonkers, NY around this same time, and was operated by John Russo. It lied about 1,000 feet south of the Hackett Quarry off Midland Avenue, near Dunwoodie. Russo's stone product was mainly building stone, and was used locally in the construction of private residences throughout the Mile Square neighborhood and slightly beyond. All cutting was also done by hand.

Another small quarry had opened in Yonkers, NY around this same time, and was operated by John Russo. It lied about 1,000 feet south of the Hackett Quarry off Midland Avenue, near Dunwoodie. Russo's stone product was mainly building stone, and was used locally in the construction of private residences throughout the Mile Square neighborhood and slightly beyond. All cutting was also done by hand.

|

In 1924, one of the longest-running quarries in Yonkers opened for business - the Rossi Quarry. The company began its 76-year operation in Yonkers as the primary supplier of foundation stones for the construction of the growing Yonkers Public School system. Rossi and Sons Westchester Granite continued to help builders during the many residential construction surges in Yonkers, Scarsdale, Eastchester, and Tuckahoe during the 1940s, 50s and 60s.

Rossi and Sons were prominent suppliers of stone for many of the bridges above the region's local parkways, that can still be seen to this day along the Sprain Brook, Hutchinson River, Bronx River, and Saw Mill River roadways. Throughout their history, Rossi and Sons supplied their granite stone in extensive quantities for the rebuilding and restoration of Yonkers City Hall, and other significant projects at Rye High School in Westchester County; The Fieldston School in Riverdale; and Fordham University in the Bronx. After closing their Yonkers quarry in the late 1990s, Rossi and Sons moved their operations to upstate New York, where later generations of the family continue to quarry and cut granite building and architectural stone to the present day, under the leadership of Peter Rossi and Louis Rossi. In fact, the family still owns and operates the same 1946 Manitowoc 3000 crane, which was dismantled from the original quarry sites in Yonkers, and moved in pieces to be reassembled upstate. |

In 1940, the DiRienzo Brothers opened a quarry on the same Yonkers road, Fullerton Avenue, and sold their stone as a facing for buildings and other ornamental purposes. The DiRienzo quarry supplied stone to residential and commercial builders throughout Westchester ounty, with one of their most significant projects being St. Mary's Immaculate Conception Church in New York City.

After closing their quarry in the early 2000s, the property has been filled-in, and is now a self storage center.

Other noteworth Yonkers quarrying firms during the 20th century were Kenneth Kosser's Mile Square Granite Quarry, Louis Pirro and Sons, Multari Stone Quarry, Barrata & D'Amato, and Quintone Ciuffetelli.

After closing their quarry in the early 2000s, the property has been filled-in, and is now a self storage center.

Other noteworth Yonkers quarrying firms during the 20th century were Kenneth Kosser's Mile Square Granite Quarry, Louis Pirro and Sons, Multari Stone Quarry, Barrata & D'Amato, and Quintone Ciuffetelli.

Other Westchester Quarry locations, outside of Yonkers

|

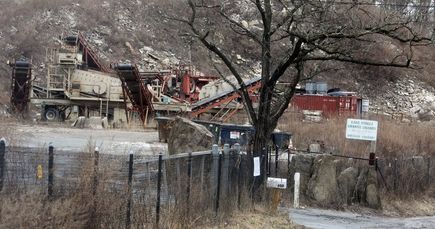

Outside of Yonkers, in the vicinity of West Harrison, another well-known Westchester granite quarry was that of Sebastiano Barrego, who purchased the Lake Street Granite Quarry in 1926. The quarry was later operated by his sons, Salvatore and Anthony Barrego. Their stone was used on projects that include White Plains High School and Good Counsel Academy.

In most recent times, while being run by the next generation under Lawrence Barrego, the quarry became a nuisance to neighbors, as more and more upscale homes were being built in the surrounding neighborhood of Lake St and Park Ln. The property has been embattled ever since; an unfortunate sign of changing times for the quarry industry in upscale Westchester County. |

The Beekman Quarry is perhaps the oldest of the quarries in all of Westchester County. It was worked in the early 1800s, and operative at intervals through the early 1900s.

The quarry was situated about 1 mile north of Tarrytown, NY, thus outside the principal area of Yonkers. It was equipped with one steam drill and a rock breaker, and extracted a blueish-grey gneiss. This quarry supplied material for several structures in Tarrytown, including many of the area churches, and the well-known stone walls that line Route 9 through the towns of Sleepy Hollow, Tarrytown and Irvington.

The quarry was situated about 1 mile north of Tarrytown, NY, thus outside the principal area of Yonkers. It was equipped with one steam drill and a rock breaker, and extracted a blueish-grey gneiss. This quarry supplied material for several structures in Tarrytown, including many of the area churches, and the well-known stone walls that line Route 9 through the towns of Sleepy Hollow, Tarrytown and Irvington.

The Reilly Quarry, owned and operated for many years by Patrick Reilly, was one of the more prominent locations for the production of building stone. Situated southwest of Tarrytown, its stone was a noticeably hard-banded dark grey gneiss. Reilly's stone was used for the Rockefeller and Archibold residences in Tarrytown.

A competing product to Yonkers Granite and Tarrytown Granite was the Harrison Diorite stone, which covered an area of several square miles in the Town of Mamaroneck, the City of Rye, and the Town of Harrison. This stone forms two nearly parallel belts, from the Village of Port Chester to Milton Point in the City of Rye; and another from the Connecticut line in Byram, CT to near the Larchmont NY railroad station. The color is dark grey with a blueish tint, and as a trade name, was and still is known as "Byram Black" granite.

Another stone band, known as the Fordham Gneiss, was a variable rock. Its band borders the Yonkers Gneiss on both sides. The color was predominantly grey and averages darker than the Yonkers stone. The Uniontown Quarry was worked for several years, and mined stone used for one of the Warburton Avenue bridges. The Fordham quarries, however, mainly furnished crushed stone for railroad ballast, as oppose to building stone.

A competing product to Yonkers Granite and Tarrytown Granite was the Harrison Diorite stone, which covered an area of several square miles in the Town of Mamaroneck, the City of Rye, and the Town of Harrison. This stone forms two nearly parallel belts, from the Village of Port Chester to Milton Point in the City of Rye; and another from the Connecticut line in Byram, CT to near the Larchmont NY railroad station. The color is dark grey with a blueish tint, and as a trade name, was and still is known as "Byram Black" granite.

Another stone band, known as the Fordham Gneiss, was a variable rock. Its band borders the Yonkers Gneiss on both sides. The color was predominantly grey and averages darker than the Yonkers stone. The Uniontown Quarry was worked for several years, and mined stone used for one of the Warburton Avenue bridges. The Fordham quarries, however, mainly furnished crushed stone for railroad ballast, as oppose to building stone.

|

In the 1900s, north of Westchester in Putnam County (near Peekskill, New York), a small area of massive granite was exposed. This granite was quarried quite extensively for building stone and foundation material. The main opening was King's Quarry, operated at one time by the King Granite Co., and later by Doern & Sons of New Rochelle, NY. Some of the buildings erected from this quarry's material are St. Joseph's Church in New York City, and the guard house at the West Point US Army Military Academy.

Granite exposures were also found on the north side of the Corlandt area, near Lake Mohegan. The quarry property of the Mohegan Granite Company was situated on the town line of Yorktown, NY, dating back to 1892. Granite was used for the construction of the dams at both the Carmel and Purdys train stations. |

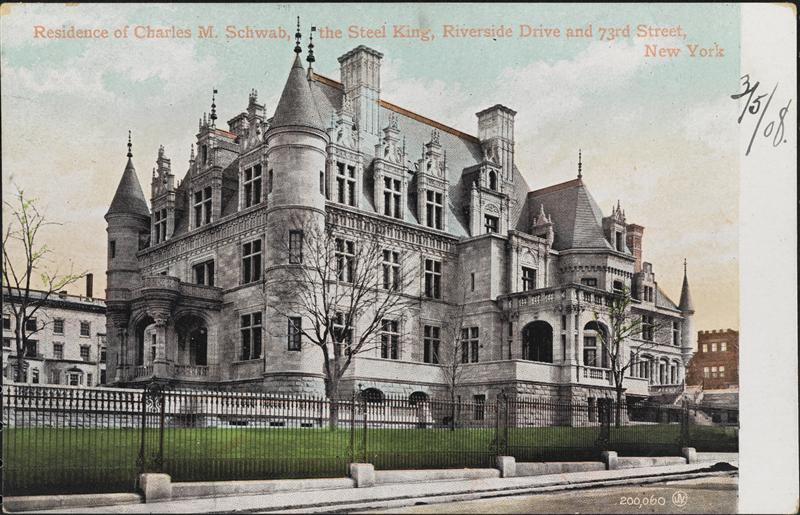

The same granite was later selected after an expansive search for material for the Cathedral of St. John the Divine, the largest church edifice in America. it was also used in the residence of Charles Schwab on Riverside Drive in New York City. The color differs from the Yonkers stone in that it is a lgihter grey of more or less a pinkish hue, and a rich yellowish brown.

The Kensico Dam, Completed in 1917

VALHALLA, NEW YORK

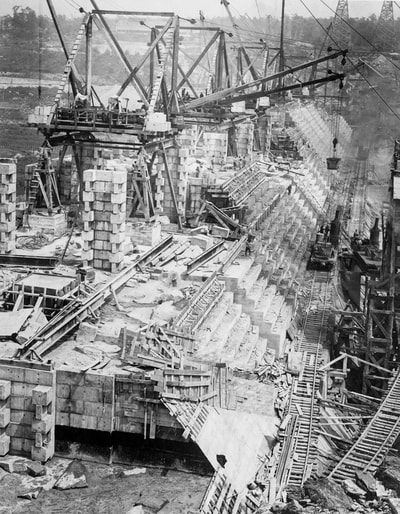

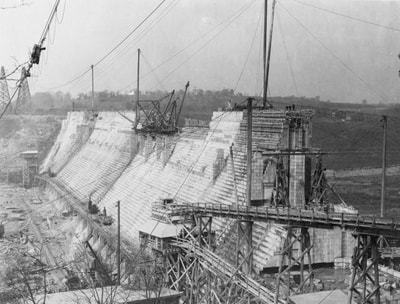

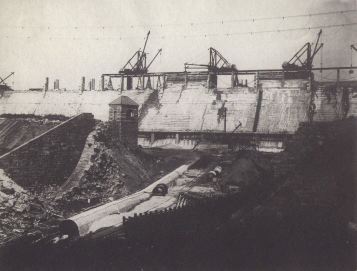

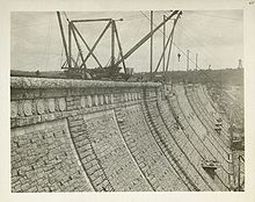

The principal quarry development of the early 1900s in the Yonkers Gneiss band of granite rock was that of H.S. Kerbaugh Inc. - the contractor for the Kensico Reservoir, which was built to form a part of the Catskill Aqueduct water supply system. To increase the capacity of the reservoir, a large, historic dam was designed that would stand 307 feet above the lowest point of its foundation, and span just over 1,800 feet long.

The structure was designed to be built in Valhalla, New York, about 24 miles north of New York City. It would be constructed of Yonkers Gneiss obtained from an area explored to the east end of the ridge. Several quarries began operation to take part in this large-scale project, including the Outlet Quarry, Ferris Quarry, Dinnan Quarry, Smith Quarry, and Garden Quarry.

The structure was designed to be built in Valhalla, New York, about 24 miles north of New York City. It would be constructed of Yonkers Gneiss obtained from an area explored to the east end of the ridge. Several quarries began operation to take part in this large-scale project, including the Outlet Quarry, Ferris Quarry, Dinnan Quarry, Smith Quarry, and Garden Quarry.

|

|

The construction of the Dam began in 1913 and was concluded in 1917, three years ahead of schedule, at a cost of more than $15,000,000. The main contractor built a work camp in Valhalla for the 1,500 men who worked on the dam. The crews were largely made up of Italian immigrants, which is the reason why Valhalla and the Town of Mount Pleasant still have a large Italian-American population to this day.

The tremendous influx of workers provided a period of prosperity for the region. New stores, rooming houses, hotels, restaurants and saloons met the needs of the workers and their families. Many of the construction families remained in the area after completion of the dam, contributing to the growth and character of Valhalla and its Italian population.

The Kensico Reservoir was acquired as parkland in 1963 from the New York City Watershed Commission, and remains the property of the New York City Department of Environmental Protection. Remnants of the original train that would haul stone from the quarries to the Dam project have been preserved for tourists along Westchester County Parkland at the Cranberry Lake Preserve, located in Valhalla, adjacent to the Kensico Dam. |

Marble Quarries of Westchester and the Hudson Valley

|

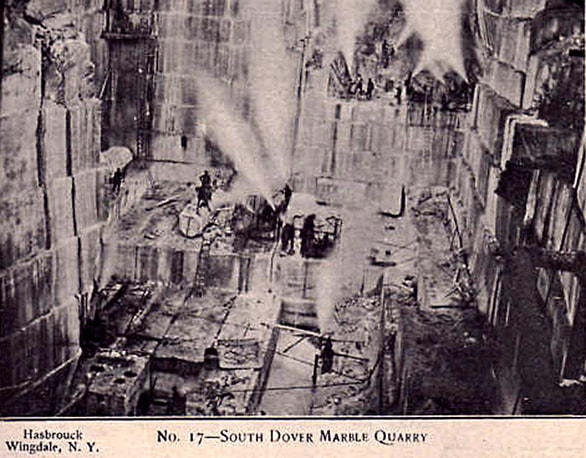

In addition to granite, marble holds its place in the region as an important quarried stone. Early quarrying of marble for building and ornamental purposes was done in the town of Dover Plains, New York (located in Dutchess County, north of Westchester and Putnam). The stone was a fine but rather loosely grained blue or white marble. The South Dover Marble Co. had large marble quarries in a direct line northeast of the Wingdale Train Station on the Harlem Railroad, dating back to the late 1890s. This stone was used for noticeable locations, including the Tiffanys Building, the Charles Building, the Essex County Court House in New Jersey, and The House of Representatives in Washington, D.C. |

SNOWFLAKE MARBLE - THORNWOOD, NY

In central Westchester County, a white marble found in Thornwood, New York and in Pleasantville, New York had supplied considerable building material for New York City, in addition to many custom homes build as far as New Orleans. Opened in 1845, the stone from this quarry was used in the world-famous St. Patrick's Cathedral of Midtown Manhattan, and the Methodist Episcopal Church in Ossining, NY.

The major facade of St. Patrick's Cathedral was built in 1879 of the stone from Thornwood. The stone itself was referred to in the industry as "Snowflake Marble," because it was "as white as the driven snow." Other matching marbles from parts of Maryland were used to supplement the stone from Pleasantville, as construction of the Cathedral neared its end.

In 1865, a new owner bought the property and named it the Snowflake Lime Works. It became one of the first industries in Thornwood, where there were shoe and pickle factories, and a landscape largely filled with dairy farms. The marble dust from the quarries was sold as high-quality agricultural lime, and also as an ingredient for stucco. In the 1920s, another owner had renamed it the Universal Marble Company.

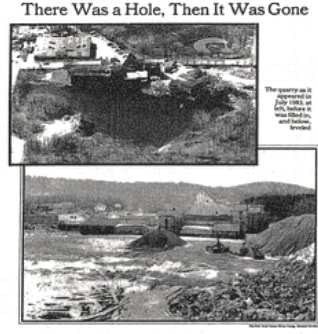

The Pleasantville and Thornwood quarries have since closed. In 1972, the Yonkers Contracting Company, run by Carl Petrillo, was excavating for the new water tunnel in Manhattan. He purchased the old quarry in Thornwood as a place to store the Manhattan Schist rock that was excavated out of NYC. A decade later, in 1984, Mr. Petrillo began filling the large pit with rock from the quarry walls. By 1985, Mr. Petrillo applied to the Town of Mount Pleasant Planning Board for approval to build a shopping center on the 10-acres of leveled-off land where the quarry once sat, in addition to rezoning of 6 acres of the site on the hill behind it, for clustered housing.

The remaining walls of marble with evident drillmarks are still evident along Broadway in Thornwood, New York, and what was once the quarry now sits a shopping center anchored by a Shop Rite grocery store. At the nearest intersection, a road was and it still named "Marble Ave" after the once-thriving industry along its path.

The major facade of St. Patrick's Cathedral was built in 1879 of the stone from Thornwood. The stone itself was referred to in the industry as "Snowflake Marble," because it was "as white as the driven snow." Other matching marbles from parts of Maryland were used to supplement the stone from Pleasantville, as construction of the Cathedral neared its end.

In 1865, a new owner bought the property and named it the Snowflake Lime Works. It became one of the first industries in Thornwood, where there were shoe and pickle factories, and a landscape largely filled with dairy farms. The marble dust from the quarries was sold as high-quality agricultural lime, and also as an ingredient for stucco. In the 1920s, another owner had renamed it the Universal Marble Company.

The Pleasantville and Thornwood quarries have since closed. In 1972, the Yonkers Contracting Company, run by Carl Petrillo, was excavating for the new water tunnel in Manhattan. He purchased the old quarry in Thornwood as a place to store the Manhattan Schist rock that was excavated out of NYC. A decade later, in 1984, Mr. Petrillo began filling the large pit with rock from the quarry walls. By 1985, Mr. Petrillo applied to the Town of Mount Pleasant Planning Board for approval to build a shopping center on the 10-acres of leveled-off land where the quarry once sat, in addition to rezoning of 6 acres of the site on the hill behind it, for clustered housing.

The remaining walls of marble with evident drillmarks are still evident along Broadway in Thornwood, New York, and what was once the quarry now sits a shopping center anchored by a Shop Rite grocery store. At the nearest intersection, a road was and it still named "Marble Ave" after the once-thriving industry along its path.

The Thornwood Marble Quarry

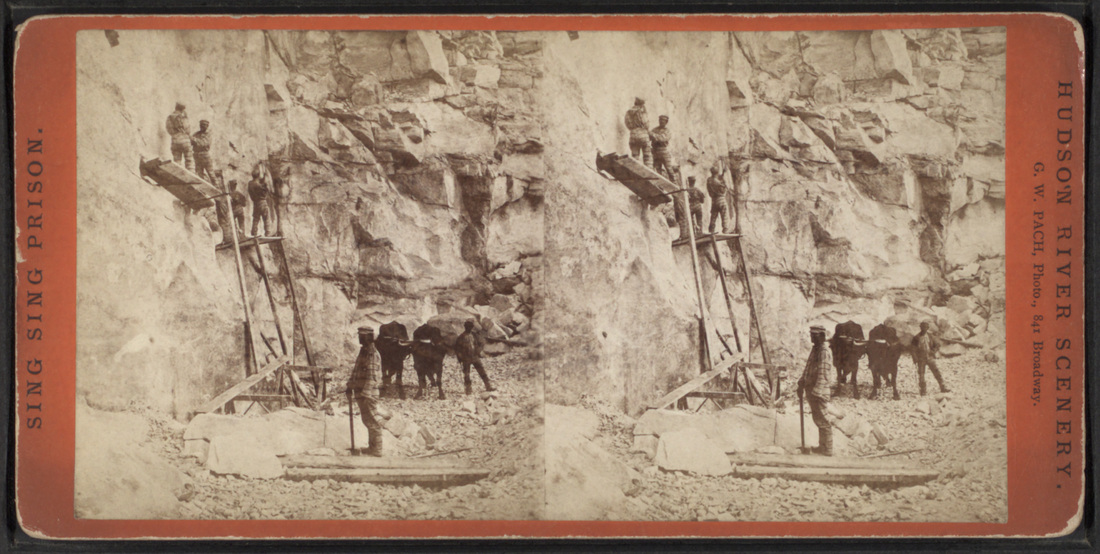

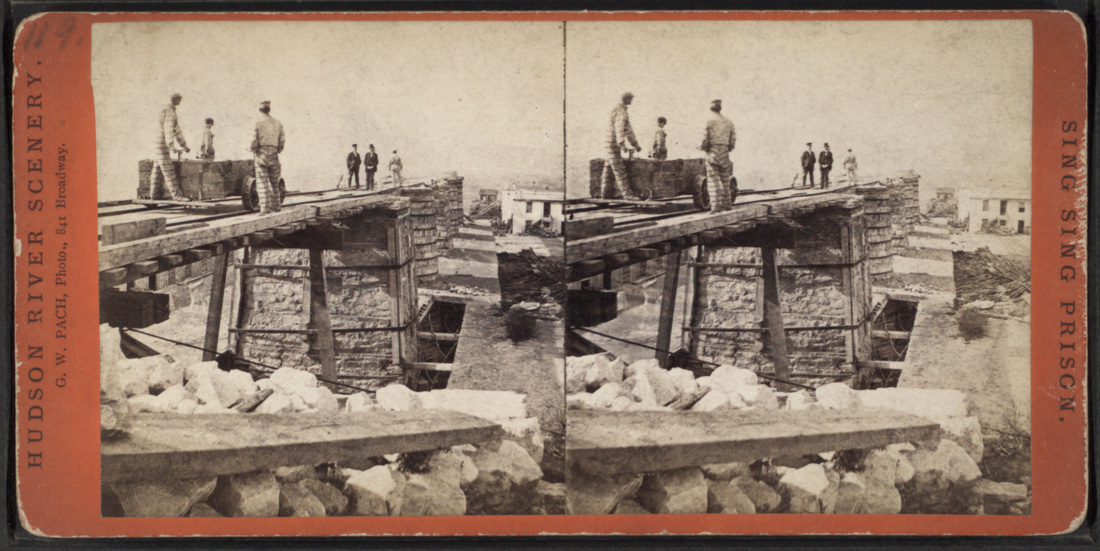

The Sing-Sing Correctional Facility

Built on a quarry with prison labor.

|

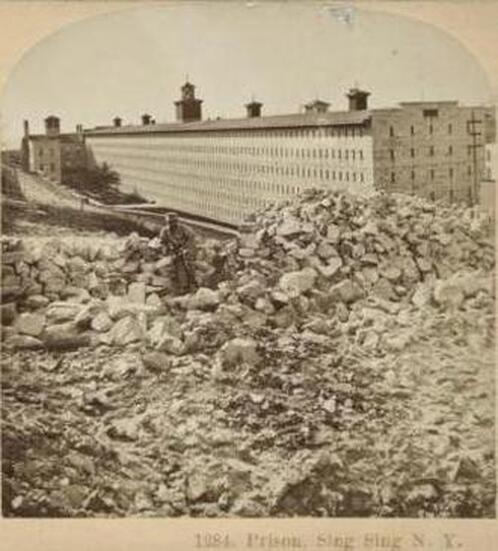

In 1825, the State of New York began construction on its third State Prison, named "Sing Sing." The location of Sing Sing was deliberately chosen due to its locale, being constructed directly in the middle of an existing large marble quarry. The village was known as Sing Sing, a Native American phrase "Sin Sinck" which means "Stone-on-Stone."

Elan Lynds, the Warden of NY's second prison - Auburn - volunteered to build the Sing Sing facility, guaranteeing that he could do it with prisoner labor at little cost to the taxpayer. In May of 1825, Lynds picked 100 convicts at the Auburn facility, barged them across the Erie Canal, and loaded them onto freighters for a trip down the Hudson to Sing Sing. They arrived "without a place to receive or a wall to enclose them." They immediately erected temporary barracks, a cook house, and carpenter and blacksmith shops. By the winter of 1826, 60 of the proposed 800 cells were completed. Two years later, Lynds had completed the entire prison with inmate labor and locally quarried marble stone, as promised. |

The first building, referred to as the 1825 Cellblock, was the largest prison in the world. It was nicknamed "The Big House" and "Castle on the Hudson," measuring 476 feet long by 44 feet wide, and four tiers high.

After construction of the first cell block building, Prisoners continued to quarry marble from the quarry, and sent stone for construction on many notable buildings, such as Lyndhurst Castle, New York University, Grace Church, the NY State Capitol Building, and the US Treasury Building. Two additional buildings were built at the prison by 1830, one containing a hospital and a kitchen, and the other a chapel for 900 men. |

We hope you have enjoyed our trip down history's lane, outlining one of the most interesting lines of work in the world - stone quarrying - right here in our home region of Westchester County.

Saracino Industries Inc. is proud to carry on this tradition, providing the world's closest material match in color, texture and overall characteristics, to the original Westchester Stone.

Saracino Industries Inc. is proud to carry on this tradition, providing the world's closest material match in color, texture and overall characteristics, to the original Westchester Stone.

Sources:

Building Stones of the New York City Area, by Sidney Horenstein

The Quarry Materials of New York – Granite, Gneiss, Trap and Marble, by David H. Newland

The Mining and Quarry Industry of New York State, by David H. Newland

The Yonkers NY Herald Statesman

The New York Times